Micro Channel Technology

A revolutionary solution conceived and patented by Pastorfrigor that can provide you with…

AWARD WINNING

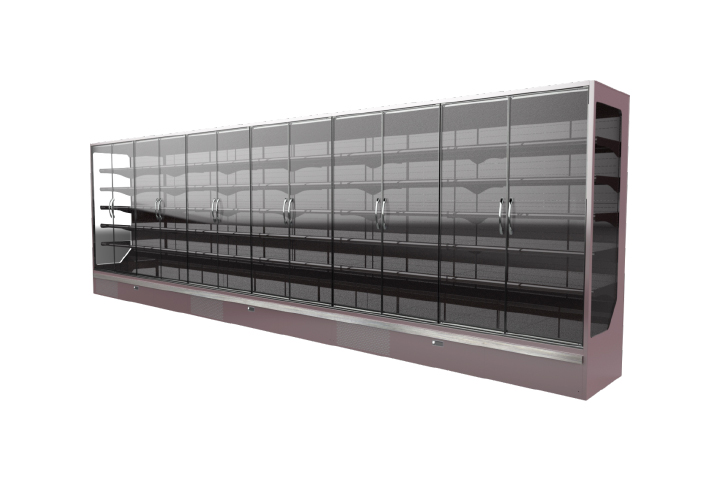

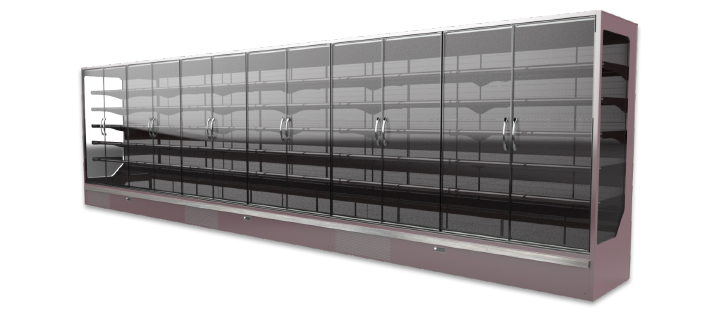

Genova Ecovision MCT

We are extremely proud to be shortlisted for two RAC awards

Refrigeration Innovation category.

Refrigeration Product of the Year category.

Flexibility

The Genova MCT is integral so you can move it around the store much easier than a remote case – brilliant if you need to re-configure your store.

BUT with a difference!

Lower energy bills

Uses 47% less energy than a standard glass door integral multideck.

That’s a saving of £440 a year for a 2.5m section.

It’s very quiet

Running noise level as low as 52dB

(that’s almost a whisper).

Less heat into your store

Total heat rejection is 2KW

so it won’t melt your chocolate!

Open your store sooner

Installation time cut by 50% due to

simpler installation, so get those

customers back in.

Future proof refrigerant

HFC’s like R404A and R407F will cease to be made from 2018. The Genova MCT uses R290 Refrigerant so you won’t increase your lifecycle costs.

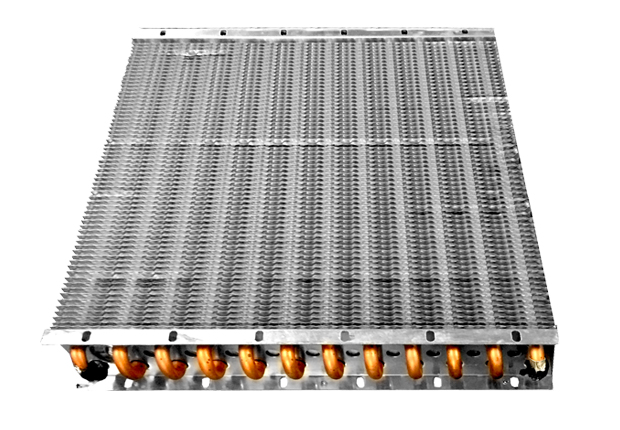

Using lightweight aluminium and with 3 years of development Pastorfrigor have now patented the Micro Channel Technology (MCT) for its new generation of plug in Genova Chillers and Freezers, all have the characteristics of much lower noise, lower energy consumption and less heat rejection compared to a standard integral cabinet, which means that you now have a viable replacement for a conventional remote system.

It is significantly smaller!

Micro Channel Evaporator

Vs

Standard Evaporator

Contact us on 01279 876919 to see how MCT can transform your future refrigeration requirements.

If you need more technical information keep reading…

Single cabinet comparison*

STANDARD |

MCT |

||

| Consumption Kw/24 | 24.5 | 12.9 | – 47% |

| GWP R407f subject to Fgas | 1,674 | 3 | |

| TEWI | 6,029 | 2,354 | – 60% |

| Energy cost (£) | 935 | 490 | – 47% |

* Figures based on GENOVA Model: LF2500 – Plug-in cabinet with glass doors

- Improved recyclability: Fully aluminium for a total weight of 6.2 kg

- Lighter weight: 30% less compared to a traditional evaporator

- Less bulk: 20% less compared to traditional evaporator, with the resulting opportunity to increase the display area

- Lower gas charge: 60% gas charge reduction for HCF refrigerants and 80% for HC ones

- Reduced consumption: On average between 25% and 50%, deriving both from a lower gas charge and the possibility of utilising efficient gases like R290/R1270 and future developments with CO2

- Lower condenser heat rejection: Less heat rejected from the condenser into the sales area means less heat to be removed by air conditioning or a more comfortable environment for non air-conditioned stores

- Minimal environmental impact: As a result of the technology providing greater possibilities of the use of HC with a GWP equal to zero

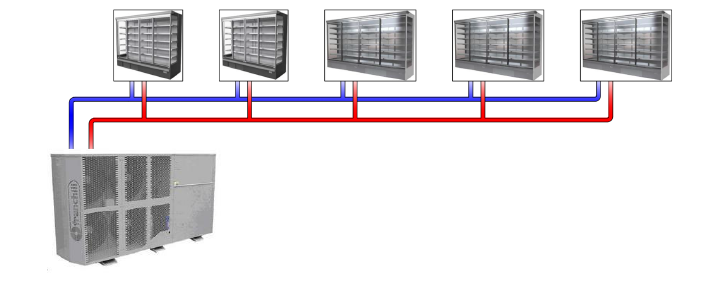

Prefer NO heat rejection?

Let us introduce a water loop solution.

Possible applications

Genova composition MOD: COMPOSITION 5 x 2500

Plug-in cabinet with remote water condenser

| Features |

| Height | 205cm |

| Depth | 85cm |

| Length | 250cm |

| Shelves | 500mm |

| Low front height | 350mm |

| Display size | 3.24 m2 |

| Display volume | 2.125 litre |

Standard Solution

Genova composition mod: composition 5 x 2500

Glass door cabinets with remote central plant and condenser

Standard copper finned evaporator and remote connection with central unit

| Features |

| Gas charge | 20 Kg |

| Consumption | 29.382 kW/Y |

| GWP | 1674 |

| TEWI | 15.514 Kg CO2/Y |

| Energy cost | 3490 £/Year |

MCT Solution

Genova composition mod: composition 5 x 2500

Plug-in cabinets with doors and remote water condenser

Microchannel evaporator with remote water condenser

| Standard solution |

| Gas charge | 0.700 Kg |

| Consumption | 23.542 kW/Y |

| GWP | 3 |

| TEWI | 11.772 Kg CO2/Y |

| Energy cost | 2451 £/Year |

Recent Comments